Shrink Wrap Machine Supplier Industrial Automatic Packaging For Sale

<what is shrink wrapping machine?>

Shrink wrap machines, also known as shrink packaging machines, are industrial equipment used to package products by applying heat to shrink a plastic film tightly around them. This process is called "shrink wrapping," and it offers several advantages, including product protection, tamper resistance, and a professional appearance.

Product lntroduction

Fully automatic sealing& slitting machine,can be used for automatic shrinking package for the production line.Film folding type,the other 3 sides can also be sealed.Constant temperature heating,quality check of the sealing can be conducted by photoelectricity unit.Optional mode between automatic material feeding and manual material feeding.This machine can be used for sealing and slitting PE,POF heat-wrapping film,resulting a fancy sealing edge,especially suitable for PDF sealing and slitting.When the size of the processed product is changed,beside making simple adjustment by using the hand wheel,no need to change any other spare parts,thus,saves the time of doing the adjustment and more easy to maneuver.Speed adjustable material feeding system at the front,and storage working platform at the rear,ensures the entire machine to be high production speed and unmanned operation.

Specifications

|

Type |

HX500BZ-R |

|

Power |

220v 50/60Hz |

|

Power input |

1.55KW |

|

Max.package height |

85mm |

|

Sealing line dimension |

650×550mm |

|

Production capacity |

15-30bags/min |

|

Pneumatic pressure |

0.5MPA |

|

Machine dimension |

2500*700*1500mm |

|

Machine weight |

600kg |

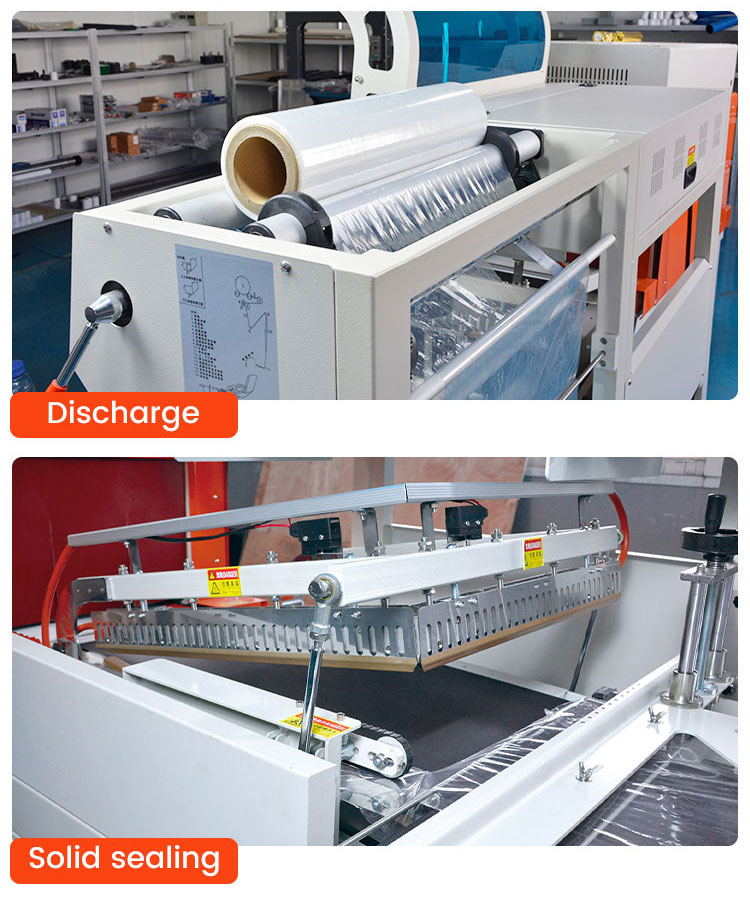

Key Features & Advantages

-

High Automation: Fully automatic feeding, sealing, slitting, and shrinking reduce manual labor and improve consistency.

-

Stable Heating System: Constant temperature control and photoelectric sensors ensure high sealing accuracy.

-

Quick Size Adjustment: Only a hand-wheel adjustment is required when changing product dimensions—no spare part replacement needed.

-

Efficient Film Compatibility: Supports PE, POF, and heat-shrink film with smooth, clean sealing edges.

-

Adjustable Feeding Speed: Front-positioned feeding system ensures steady operation for different product sizes.

-

Rear Storage Platform: Helps maintain a continuous production rhythm during high-speed packaging.

How the Machine Works:

-

Product is automatically fed into the conveyor.

-

Shrink film wraps around the product.

-

Heating system seals and slits the film precisely.

-

Product enters the heat tunnel for shrinking.

-

Finished package exits neatly for boxing or delivery.

Technical Working Principle:

The shrink wrapping process works by using heat to contract the film tightly around the product. When the sealed package enters the heat chamber, the molecular structure of the shrink film reacts to the temperature and shrinks uniformly. This creates a secure, form-fitting package that enhances protection and improves product presentation. The machine ensures stable temperature distribution, allowing the film to shrink evenly without wrinkles or burn marks.

Packaging Effects & Benefits:

Shrink packaging delivers several superior effects:

-

Tight and strong protection for transportation.

-

High transparency that enhances product visibility.

-

Moisture-proof and dust-proof sealing.

-

Scratch resistance for sensitive surfaces.

-

Retail-ready appearance suitable for supermarkets and e-commerce.

Comparison: Traditional Packaging vs. Shrink Wrapping:

| Comparison Item | Traditional Packaging | Shrink Wrap Machine |

| Material Cost | Higher | Lower |

| Packaging Speed | Slow, manual | Fast, automatic |

| Appearance | Basic | Professional, clean |

| Protection | Moderate | Excellent seal protection |

| Labor Need | High | Low |

Why Choose Sailingpaper Factory?

-

19+ years of manufacturing experience

-

CE / ISO certified factory

-

Strong R&D and engineering support

-

Fast delivery and stable supply capability

-

Customizable machine configurations

-

Professional after-sales service with global technical support

Safety & Quality Assurance:

-

Overheating protection

-

Anti-cut safety system

-

Emergency stop button

-

Continuous sealing strength testing

-

Durable structural design for 24-hour operation

Machine Durability & Build Quality:

The machine frame is built with reinforced steel structure for long service life.

-

Anti-rust surface treatment

-

High-temperature-resistant conveyors

-

Industrial-grade motors

-

Wear-resistant bearings and belts

This ensures stable performance even under continuous 24-hour operation.

After-Sales Service & Support:

We provide full-service after-sales support, including:

-

Online video training

-

Real-time technical guidance

-

1-year warranty

-

Spare parts supply

-

Long-term maintenance support

-

Remote troubleshooting assistance

Logistics & Packing of the Machine:

For international customers, the machine is packed in:

-

Export-grade wooden cases

-

Shock-proof internal padding

-

Moisture-proof packaging

Ensuring safe delivery to all countries.

FAQ:

Q1: What film thickness is supported?

A: The machine supports film thickness from 12μm to 80μm depending on material.

Q2: Can the machine run continuously?

A: Yes, industrial-grade components support 24-hour continuous operation.

Q3: How long does installation take?

A: Standard installation can be completed within 1–2 hours.

Q4: Does it support printed shrink film?

A: Yes, printed shrink film is fully supported.

Inquiry Guide:

Looking for a reliable automatic shrink wrap machine for your factory?

Contact us now for:

-

Best price

-

Technical details

-

Video demonstrations

-

Custom configurations

-

Free consultation

Click “Contact Supplier” to get your quotation today!

<why use shrink wrap machine to sealing product?>

Preservation of freshness and extended shelf life: shrink wrap machine create hermetically sealed packages that prevent air and moisture from entering the interior of the package.

Protection against contamination and external pollution: Sealed packaging effectively prevents external contaminants such as dust, bacteria and micro-organisms from entering the product.

Provides protection against counterfeiting: Thermoplastic packaging often provides an effective protection against counterfeiting, as signs will show up as soon as the package is opened or tampered with.

Enhances appearance and sales appeal: Thermoplastic packaging can provide a professional and attractive appearance to the product, which can help to increase sales.

Packaging to secure or bundle multiple products: Thermoplastic packaging machines can be used to package multiple products, such as combo packs, kits or multipacks.

Reduced wastage: Since thermoplastic packaging can pack products more tightly, it reduces material wastage, reduces the size of the package and reduces packaging costs.

Reduced wastage: As thermoformers can pack products more tightly, there is less material waste, smaller pack sizes and lower packaging costs.

FAQ

Q: Are you a factory or trading company?

A: We are the biggest converting factory in south of China

Q: Can you do design for me?

A: our professional designer will make artwork for cartons and printing.

Q: Can I have a sample order for paper roll?

A: sample pacakge with different quality are free for picking up

Q: What about the lead time?

A: Mass production time needs 2-3 weeks.

Packaging & Delivery

Packaging Detail:Plastic sealed, cardboard box, able to be customized at customers' requests applications

Delivery Detail:Within 15days after order confirmed

About us

1、Sailing paper locate in shenzhen China,specializes in coating and converting of thermal paper, carbon less paper, label rolls both plain and printed, etc. We are an exporter in this particular line for many years.

2、Our goal: Exceeding your expectations

3、Sailing paper strives to help you on saving your time and money .

Your inquire will be answered within 24 hours.Any inquiries we are happy to reply, pls send your questions and orders. Wishing to be your long-business partner.